Quality Assurance

To beat your competition, make good quality your mission

At Nisha Enterprise, quality is our priority. We have maintained flawless service with zero-defect products. Our primary focus remains on the continuous enhancement of the total quality management. With such efficiency and effectiveness we have attained the basic parameters and the customer satisfaction to a large extent. Maintaining customer satisfaction has always been our strong belief which has increased our customer base.

All products are inspected at all stages of manufacturing for defect free surface quality. A team of trained supervisors and quality control inspectors ensures that the quality is maintained at all the stages of production. Our plant has maintained ISO 9001:2015, a certification of quality management systems maintained by the International Organization of Standardization and administered by certification and accreditation bodies.

Nisha Enterprise is committed to the adherence of all processes through process improvement plans. Our process improvement plans allow allocation of human resources and other facilities to improve the quality of our products. This results in implementing good practices and maintaining the highest standards of quality at every stage.

Why Choose Us

We’re Dedicated To

Provide Quality Products & Services.

Our primary goal is to provide highest quality products with good customer centric service. We will achieve this goal by continuous monitoring and improving our performance, which are based on client needs and tough objectives. We are responsive for customer needs and provide satisfaction with our sincerity and ceaseless efforts.

-

Reliability

Transparency Service

-

Materials

100% Quality Products

-

Expert Staff

Trained & Experienced

-

Accredited

ISO Certified Company

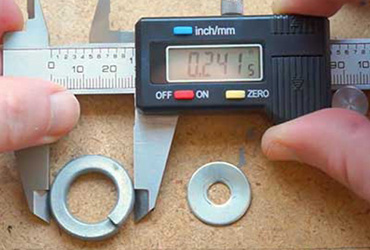

Quality Control

After product produced, it has been send to QC Department. Quality Control Supervisor will check all dimensions and measurements on the basis of various quality checking methods. If reports are under required tolerance then material will be sent to next department.

Quality Instruments

Instruments are the heartbeats of industry, to assure good quality, Quality Instruments are required. Company has invested a good amount behind this to have majority type of Inspection instruments including all instruments and gauges along with the profile projector and other sensitive instruments.

Quality Inspection

Company has unique Inspection facility to achieve the goal to zero defects and rejection of any products manufactured. Well experienced and regularly trained technocrat engineers, carry out the Inspection on each Individual product. Batch Inspection is not permitted in the company.

Packing & Dispatch

Packaging is the most important aspect. After Inspection, each order is directed to a particular packing location. The completeness of whole order can be checked here optionally. Than the packing list gets printed to be included into the packing and the whole order is packed and dispatched.